Cold Thermal Storage and Peak Load Reduction for Office Buildings in Saudi Arabia

2014-07-29NabilAbdelShafiRamzyObaidandIbrahimJomoah

Nabil Y.Abdel-Shafi,Ramzy R.Obaid,and Ibrahim M.Jomoah

1.Introduction

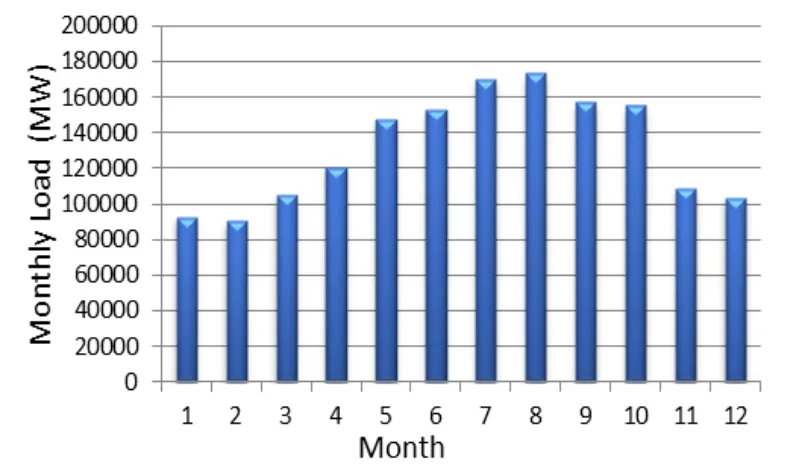

Over the last decade,the demand for comfort cooling systems has been rapidly increasing in the Kingdom of Saudi Arabia(KSA)due to improved living standards.The demand for electricity in KSA is continuously increasing,growing at an average rate of 8% per year,the world average being 2.7%.It has been reported that 20~40 billion SR(Saudi Rial)investment per year would be required to the electrical infrastructure in the coming years if the projected growth in demand is not blocked.In KSA,the peak electricity demand increased by 10% from 30 GW in 2005 to 48 GW in 2011.In 2021,as shown in Fig.1,the peak demand will reach 75 GW,an increase of 5.4%compared to 2011[1].A major portion of this load is compounded by artificially low energy prices and a hot climate,both of which encourage more energy consumption.Fig.2 shows the measured average values of monthly electrical energy consumption in the City of Jeddah in the year 2011.It can be observed that the summer months between June and October have consistently higher loads than the non-summer months,and this is in primarily due to the air conditioning(AC)load.Moreover,it has been estimated that 70% to 75% of the total energy consumption in KSA is used for indoor AC,often during the hours of peak power demand.The cooling load is observed to be at its peak in KSA during the period from 13:00 hours to 17:00 hours.

Fig.1.Variation of yearly peak load demand in KSA.

Fig.2.Variation of monthly average load demand of Jeddah city in the year 2011.

Thermal energy storage(TES)is considered to be one of most advanced energy technologies and increasing attention has been devoted to the utilization of this essential technique for AC applications[2],[3].In recent years,a number of cold storage systems such as chilled water storage,ice storage,and eutectic salts storage have been developed.Water is chilled or ice is made during the night to either replace or augment building cooling equipment during the day.Cold thermal energy storage(CTES)can either be full storage systems,where all on-peak cooling loads are satisfied from storage,or partial storage systems,where all cooling loads above a certain level are satisfied from storage.It is estimated that the power consumption for AC systems in USA is about 36% of the electric power supplied to office and commercial buildings.Therefore,the savings for the consumers and the power company may be billions of dollars per year,if ice thermal storage systems are used for new installations and retrofit[4].

Many studies have been carried out by various researchers in the field of CTES systems.Laybourn et al.[5],has described an ice storage unit in an 1865 m2single story office building in California,and has shown its ability to shift the peak demand of the building,while maintaining the cooling requirements.Liu et al.compared the field performance of TES systems with the conventional systems[6].The field data for several TES sites have been analyzed by using a ‘mean-day’ and ‘peak-day’ approach.Energy usage,direct power costs of ice,chilled water,and eutectic salt systems have been compared to that of conventional systems and have concluded that the TES systems is better than other systems.Hasnain et al[7].discussed the means of reducing the peak electrical demand in large Saudi office buildings by using CTES.It was observed that the incorporation of a partial ice storage system in office buildings in the city of Riyadh(KSA)can reduce the peak time electrical power demand and the peak time cooling load in the range of 10% to 20% and 30% to 40%,respectively.Also Sebzali has studied the impact on the energy performance of air cooled chillers of using ice cold thermal storage with different operating strategies in Kuwait[8].

Numerous economic studies and cost analysis of CTES systems and their practical applications have been undertaken by many researches.Navon et al.and Fang et al.have discussed the economic aspects of the optimal design for AC with thermal energy[9],[10].Moreover,Habeebullah has investigated the economic feasibility of retrofitting an ice thermal storage system for the AC plant of the Grand Holy Mosque of Makah in Saudi Arabia[11].The capital recovery factor was calculated for 10% interest rate and the payback period of 10 years.Full and partial load storage scenarios have been considered.The results have shown that with the current fixed electricity rate,there is no gain in the introduction ice storage systems for both storage schemes.

Combined utilization of an incentive tariff model and storage technology has shown reasonable daily savings for full load storing scheme.However,savings out of partial load storage were not seen to be attractive even with the structured base tariff.

Office buildings need heat ventilation air conditioning(HVAC)systems for the comfort of occupants and smooth flow of work.HVAC systems play a major role in the energy consumption of office buildings in KSA.This paper demonstrates the effectiveness of the CTES techniques,applied to the office buildings in King Abdul Aziz University in Jeddah,utilizing its hourly load profile calculated according to the building specifications and the building usage.CTES operation conditions are designed according to the building load demand profile,storage capacity,and peak/off peak period.The potential cost savings attributed to the use of CTES system are evaluated,and are compared to those of a stratified cold storage and the “no storage” systems.

2.Descriptions of Test Building

In this paper,the effect of thermal energy storage opportunities is investigated with reference to building No.119,a five-story office administration building in King Abdul Aziz University(KAU)Jeddah,KAU is one of the largest educational institutions in KSA,with its latitude of 29:12 N degrees and longitude 39:7 E degrees.The total floor area of the building is 1415 m2and the floor to floor height at each level is 2.5 m.The walls of the building consist of the 200 mm concrete block and 50 mm polyurethane.The roof is flat and consists of the 150 mm heavy weight concrete deck with the 25 mm insulation,suspended ceiling with no insulation.Double glazed fixed windows with 12 mm air space in between are used in the building.Various major electrical loads used in this building include computers,teaching aids,laboratory equipment,printers,lamps,and air conditioner units.Table 1 summarizes the physical characteristics of the office building No.119.

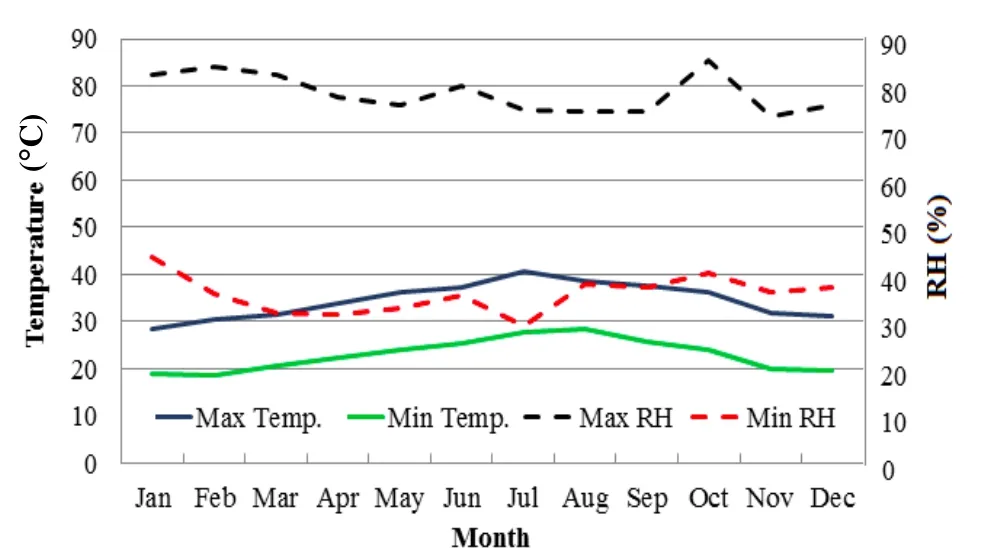

A load profile for the selected building is developed to evaluate the cooling and storage requirements of the building.Building office hours are 06:30 a.m.to 15:30 p.m.and the number of occupants exceeds 100.In order to provide an estimate of the cooling,the load profile of the building is under investigation.The weather data of theJeddah City for the year 2011 shown in Fig.3 is utilised.This figure shows the maximum and minimum relative humidity(RH)and the ambient temperature at the Jeddah area.

Table 1:Physical characteristics of the office building No.119

Fig.3.Variation of monthly weather data of Jeddah city in 2011.

Fig.4.Variation of hourly average cooling load of the office building during the months from January to December.

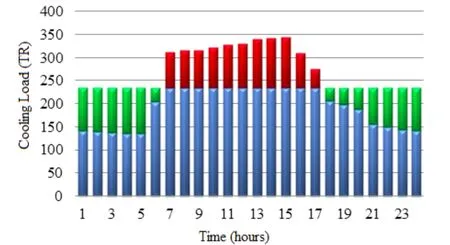

Fig.5.Hourly average hourly cooling load demand of the office building in July.

The cooling load of the selected building is supplied by forty three air handling units(AHUs)serving the different zones of the building.For each zone in the building,a separate profile is defined for the occupants,lighting,and the appliances.From the cooling load profiles of the office building for the months from January to December,shown in Fig.4,it can be seen that the hourly average cooling load in the month of July has the maximum cooling load of 343 ton refrigeration(TR).Fig.5 represents the hourly average load profile of an office building,having a peak design load of 343 TR for July.As it can be seen from this figure for a conventional AC system operation,the chiller operates throughout the day to provide sufficient cooling to meet the cooling load of the office building,and for most of the time the chiller operates at partial load.

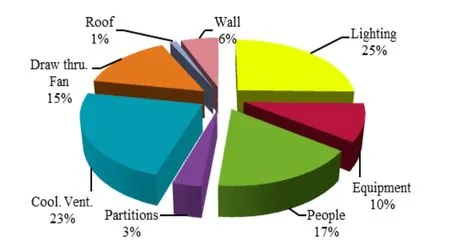

Fig.6.Proportions of the maximum cooling load of the building at 15:00 in the peak time.

As shown in Fig.6,the maximum cooling load of the building during peak hours is divided into eight components:people,lighting,appliances etc.The ventilation consists of about 23% of the total load and forms a significant portion of the man cooling load.Furthermore,these figures also indicate that a major portion of the cooling energy is required during the peak hours,whereas a minimal energy is required during the off-peak hours.The daytime cooling load can easily be shifted to operate in night time by the incorporation of the cold thermal storage system with the existing central AC system.

3.Selection of Type of Cool Thermal Storage System

The possible approaches to cool thermal storage for cooling buildings were classified according to the type of thermal storage medium and storage technologies in [12].The most common cool storage media are water,ice,and eutectic salts.Although,eutectic salts are available,their use is limited because of the technical problems due to uneven melting.Storage technologies include chilled water tanks,ice harvesting,ice-on-coil,encapsulated media,and slurry systems.

Depending on the needs of the building and the electric rate structure,there are several operating strategies available for charging and discharging storage to meet cooling load during peak hours.Hence,the operating strategy determines what portion of the load at any given time is met by the storage and what portion is met by direct chilling[13],[14].The operating strategies of cool thermal storage systems can be either full storage or partial storage,depending on the amount of cooling load shifted from on-peak to off-peak periods.Partial storage may be using either a storage priority or a chiller priority.Full storage systems are designed to meet all the on-peak cooling loads from the cool storage.With a partial-storage strategy,the capacity of the chiller is significantly less than the maximum load.The chiller only meets part of the on-peak cooling load and the remaining part is met by the cool storage[14].Such operating strategies can be further subdivided into the load-leveling operation and the demandlimiting operation.Fig.7 shows the operation strategies of the basic cool thermal storage for each scenario.

Fig.7.Operation strategies of a basic cool thermal storage system.

The selection of a CTES for a particular application is based on the major factors such as technical,environmental,economic,energetic,sizing,integration,and storage duration[3].In this investigation,partial and full storage strategies are examined for both ice and chilled water storage systems.For the partial storage strategy,the loadleveling and 50% demand-limiting strategies are examined.The factors affecting the design of CTES systems for office buildings are discussed as follows.

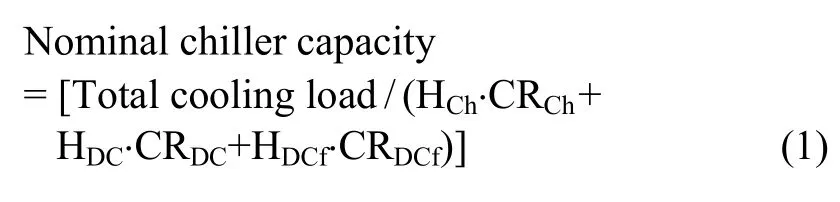

The size of the chiller and storage capacities for each operation strategy can be obtained for the ice and chilled water storage systems as

where HChis the storage charging time,CRChis the chiller’s capacity ratio when charging storage,HDCis the direct cooling during on-peak period,CRDCis the chiller’s capacity ratio when direct cooling during on peak period,HDCfis the hours of direct cooling during off-peak period,and CRDcfis the chiller’s capacity ratio when direct cooling during off-peak period.

The chiller capacity ratio(CR)is the ratio of the cooling production of the chiller at any hour to the chiller nominal capacity.Hence,for an ice storage system,the capacity ratio when charging(CRCh)is chosen as 0.65,and when direct cooling(CRDC)is chosen as 1.0 of the nominal chiller capacity.For the chilled water storage system,the capacity ratios when charging(CRCh)and when direct cooling(CRDC)of the chiller are assumed to be equal to 1,similar to a conventional AC system[11].If the resulting nominal chiller size is greater than the cooling load for any hour of operation in direct cooling mode,the chiller size is to be recalculated.The flow chart for the feasibility assessment process shown in Fig.8 can be used to determine which system can provide the most economical solution[15].Storage capacity depends on both the chiller output and the number of charging hours available for storage.Therefore,the required storage capacity for each operation strategy is calculated as

where TCDCis the total capacity when direct cooling during the on-peak period,TCDCfis the total capacity when direct cooling during the off-peak period,and THChis the direct cooling while simultaneously charging.

4.Results and Discussion

Fig.5 represents the hourly load profile of the office building No.119,having a peak design load of 343 TR(at 15:00 hours)with a total cooling requirement of 5610 ton hours in a 24-hour cooling period,as given in Table 2.Thus,the daily cooling demand of the building requires the chillers with the average actual capacity of 234 tons.The chiller nominal capacity is to be higher than the required value as chiller operates at less than nominal capacity.

Fig.8.Flow chart detailing the feasibility assessment process.

Table 2:Hourly AC loads of the office building in July

Table 3:Calculated nominal chiller size and storage capacities for an office building

Fig.9.Profiles of the cooling load of the chillers partial storage,load-leveling operating strategies,in chilled water storage.

Table 2 shows the hourly AC load requirement for building No.119 for July.It can be seen that the storage discharging takes place from 7:00 to 17:00 during which the system load and electricity demand are both high,thereby reducing the total electrical energy consumption.In this case,using the system load profiles of an office building shown in Fig.5,and applying the selected charging and discharging time periods,the size of the chiller capacity for each operating strategy is computed for the ice and chilled water storage systems for various operating conditions and are summarised in Table 3.From this table,it is observed that the partial storage demandlimiting operation with 50% capacity ratios has the maximum chiller capacity.Further,partial storage loadleveling operation has the lowest chiller and storage sizes,and it reduces the peak electrical power demand.The chiller and storage sizes in full storage are larger than those in the partial storage load-leveling operation and smaller than those in the demand-limiting operation with 50%capacity ratios operations.It can also be observed that the stored cooling load is equal to the available load from the chiller after satisfying the off-peak cooling load.

The storage capacity for the operation strategy in Fig.9 is equal to the area between the cooling load and the cooling production during the charging hours.This profile shows how the cooling load can be redistributed to minimize the peak demand.In this case,the chiller starts to charge the storage at 6:00 pm when the chiller cooling production in the charging mode is higher than the system cooling load,and ends at 7:00 am,so the chiller takes approximately 13 hours to charge the storage tank.

The bar chart of the hourly variation of the building cooling load of the chiller is shown in Fig.9,which illustrates the profile of the cooling load of the chillers operating in the partial storage load leveling for chilled water.Costs for cold storage systems vary significantly because of the many different technology options and significant size economies-of-scale for some components,in addition to the variation in site-specific conditions and individual vendor offerings.Table 3 shows the details of various operating strategies and the corresponding chiller and storage capacities computed for the office building No.119.The following steps can be used to prepare rough estimates for the six operating strategies of cold thermal storage system that are selected for the present study.In general,all systems have a chill-generating device and a chill storage device.

The installation cost of the storage tanks for chilled water and ice storage in Saudi Arabia market can be adopted with SR 150/TR hour and SR 225/TR hour,respectively[9],[13].The installation cost of the CTES systems in Saudi Arabia market can be adopted with SR 3000/TR that includes the supply and installation of chillers,pumps,cooling towers,ice tanks,piping & valve fittings,electrical and control system cost,and chemical treatment.The average annual maintenance cost for the conventional AC system is approximately 30 SR per ton per year,based on 20 years of useful chiller-life.In the case of CTES,the chilled water system is about 40 SR per ton per year,and the ice storage system is 50 SR per ton per year[7],[11],[15].The summary of these results is presented in Table 4.

Table 4:Summary of the economic analysis of an office building

Upon comparison of the installation and maintenance costs of the conventional system with the CTES systems,it can be observed that the partial storage demand-limiting operating strategies with 50% capacity ratios cost has the highest cost followed by the conventional system.The results indicate that the chilled water partial storage is significantly lower than the other strategies.It is observed that the cost saving in the load-leveling storage strategy is significantly lower than the other strategies.Additionally,the results in Table 4 indicate that the total in saving cost can reach up to 16.3% in the best condition of the partial storage-load leveling and chilled water.

5.Conclusions

This paper has dealt with the applications of cold thermal storage techniques for the reduction of the electric energy consumption in the office buildings in Saudi Arabia during the peak load period.The investigations have been carried out on the basis of the calculated load profile and the climatic conditions in Saudi Arabia.The chilled water partial storage,load-leveling approach,is seen to be the most attractive and economic option for the office buildings in this country.In addition to the peak load reduction,this technique also enables the reduction in the capacities requirements of the system,and hence in the capital investment as well as in the operation cost.The application of CTES may be made more economic from the consumer’s perspective,if different electric tariffs are applied for the peak and off-peak periods in Saudi Arabia.

[1]Annual Report,Saudi Electricity Company,2011.

[2]M.M.Hussain,I.Dincern,and S.M.Zubair,“A feasibility study of using thermal energy storage in a conventional air-conditioning system,” Int.Journal of Energy Research,vol.28,no.11,pp.955–967,2004.

[3]I.Dincer and M.A.Rosen,Thermal Energy StorageSystems and Applications,2nd ed.Chichester:John Wiley &Sons,Ltd.,2011.

[4]T.S.Wan.(April 1994).Ice thermal storage in air conditioning application fundamentals.[Online].Available:http://thomastswan.files.wordpress.com/2010/01/article-1-fu ndamental.pdf

[5]D.R.Laybourn and V.A.Baclawski,“The benefits of thermal energy storage for cooling commercial buildings,”IEEE Trans.on Power Apparatus and Systems,vol.PAS-104,no.9,pp.2356–2360,1985.

[6]K.Liu,H.Güven,A.Beyene,and P.Lowrey,“A comparison of the field performance of thermal energy storage(TES)and conventional chiller systems,” Energy,vol.19,no.8,pp.889–900,1994.

[7]S.M.Hasnain,S.H.Alawaji,A.M.Al-Ibrahim,and M.S.Smiai,“Prospects of cool thermal storage utilization in Saudi Arabia,” Energy Conversion & Management,vol.41,no.17,pp.1829–1839,2000.

[8]M.Sebzali,“Assessment of cool thermal storage strategies in Kuwait,” Ph.D.dissertation,School of Engineering,Cranfield University,Bedford,UK,2007.

[9]A.V.Novo,J.R.Bayon,D.Castro-Fresno,and J.R.Hernandez,“Review of seasonal heat storage in large basins:water tanks and gravel-water pits,” Journal of Applied Energy,vol.87,no.2,pp.390–397,2010.

[10]G.Y.Fang and H.Li,“Economic analysis of cool storage air-conditioning systems,” Int.Journal of Architectural Science,vol.5,no.2,pp.47–51,2004.

[11]B.A.Habeebullah,“Economic feasibility of thermal energy storage systems,” Energy and Buildings,vol.39,no.3,pp.355–363,2007.

[12]C.E.Dorgan and S.E.James,Design Guide for Cool Thermal Storage,American Society of Heating,Refrigeration and Air-Conditioning Engineers,Atlanta,1994.

[13]I.Dincer,“On thermal energy storage systems and applications in buildings,” Energy and Buildings,vol.34,no.4,pp.377–388,2002.

[14]B.He,“High-capacity cool thermal energy storage for peak shaving―A solution for energy challenges in the 21st century,” Ph.D.dissertation,Department of Chemical Engineering and Technology,Kungl Tekniska Hö,Stockholm,Sweden,2004.

[15]Cool Storage Technology Guide,Electric Power Research Institue,Palo Alto,2000.