Biological Nutrient Removal in a Full Scale Anoxic/Anaerobic/Aerobic/ Pre-anoxic-MBR Plant for Low C/N Ratio Municipal Wastewater Treatment*

2014-07-18胡香,谢丽,张善发等

Biological Nutrient Removal in a Full Scale Anoxic/Anaerobic/Aerobic/ Pre-anoxic-MBR Plant for Low C/N Ratio Municipal Wastewater Treatment*

HU Xiang (胡香)1, XIE Li (谢丽)1,**, SHIM Hojae2, ZHANG Shanfa (张善发)3and YANG Dianhai (杨殿海)1

1State Key Laboratory of Pollution Control and Resources Reuse, Tongji University, Shanghai 200092, China

2Department of Civil and Environmental Engineering, Faculty of Science and Technology, University of Macau, Taipa, Macau SAR, China

3Shanghai Urban Construction Design and Research Institute, Shanghai 200125, China

A novel full scale modified A2O (anoxic/anaerobic/aerobic/pre-anoxic)-membrane bioreactor (MBR) plant combined with the step feed strategy was operated to improve the biological nutrient removal (BNR) from low C/N ratio municipal wastewater in Southern China. Transformation of organic carbon, nitrogen and phosphorus, and membrane fouling were investigated. Experimental results for over four months demonstrated good efficiencies for chemical oxygen demand (COD) and4NH-N+removal, with average values higher than 84.5% and 98.1%, respectively. A relatively higher total nitrogen (TN) removal efficiency (52.1%) was also obtained at low C/N ratio of 3.82, contributed by the configuration modification (anoxic zone before anaerobic zone) and the step feed with a distribution ratio of 1︰1. Addition of sodium acetate into the anoxic zone as the external carbon source, with a theoretical amount of 31.3 mg COD per liter in influent, enhanced denitrification and the TN removal efficiency increased to 74.9%. Moreover, the total phosphate (TP) removal efficiency increased by 18.0%. It is suggested that the external carbon source is needed to improve the BNR performance in treating low C/N ratio municipal wastewater in the modified A2O-MBR process.

biological nutrient removal, low C/N ratio wastewater, membrane bioreactor, denitrification, external carbon source

1 INTRODUCTION

Biological nutrient removal (BNR) from municipal wastewater is frequently conducted in an anaerobic/anoxic/aerobic (A2O) process with respective reactors linked in series [1]. In the BNR system, the availability of usable carbon/energy in wastewater determines the capability of nitrogen and phosphorus removal [2]. One problem associated with municipal wastewater especially in Southern China is the low carbon/nitrogen (C/N) ratio, leading to low removal efficiency for nutrient. Thus new process configuration and operational strategies have been developed based on the conventional A2O process to make the best use of available carbon source in municipal wastewater. It is showed that higher removal efficiencies for nitrogen and phosphorus could be obtained by reversing the positions of anaerobic and anoxic zones, and this modified A2O process (anoxic/anaerobic/aerobic) has been widely applied for the upgrading and reconstruction of many wastewater treatment plants (WWTPs) in China [3-5]. Other researches on BNR systems suggest that step feed mode, i.e., allocation of influent chemical oxygen demand (COD) to the anoxic zone for denitrification and the anaerobic zone for phosphate release, is an efficient way to enhance the biological nitrogen and phosphorus removal [2, 6, 7]. Higher total nitrogen (TN) and 85% and 95% respectively, were obtained using the step feed strategy in the A2O process [8]. The optimal distribution ratio (0.15) was applied to treat the low C/N ratio (averaged at 3.6-3.8) wastewater, with the TN removal efficiency increased by 13.2% compared to that without the step feed mode under the same conditions. In addition, results from the UCT (University of Cape Town) type membrane bioreactor (MBR) further demonstrated that the step feed modification, with 40% of the low-strength influent (with influent COD concentration of 283 mg·L−1) diverted to the anoxic zone, could increase the TN and total phosphate (TP) removal efficiencies from 58% to 77% and from 39% to 72%, respectively [9].

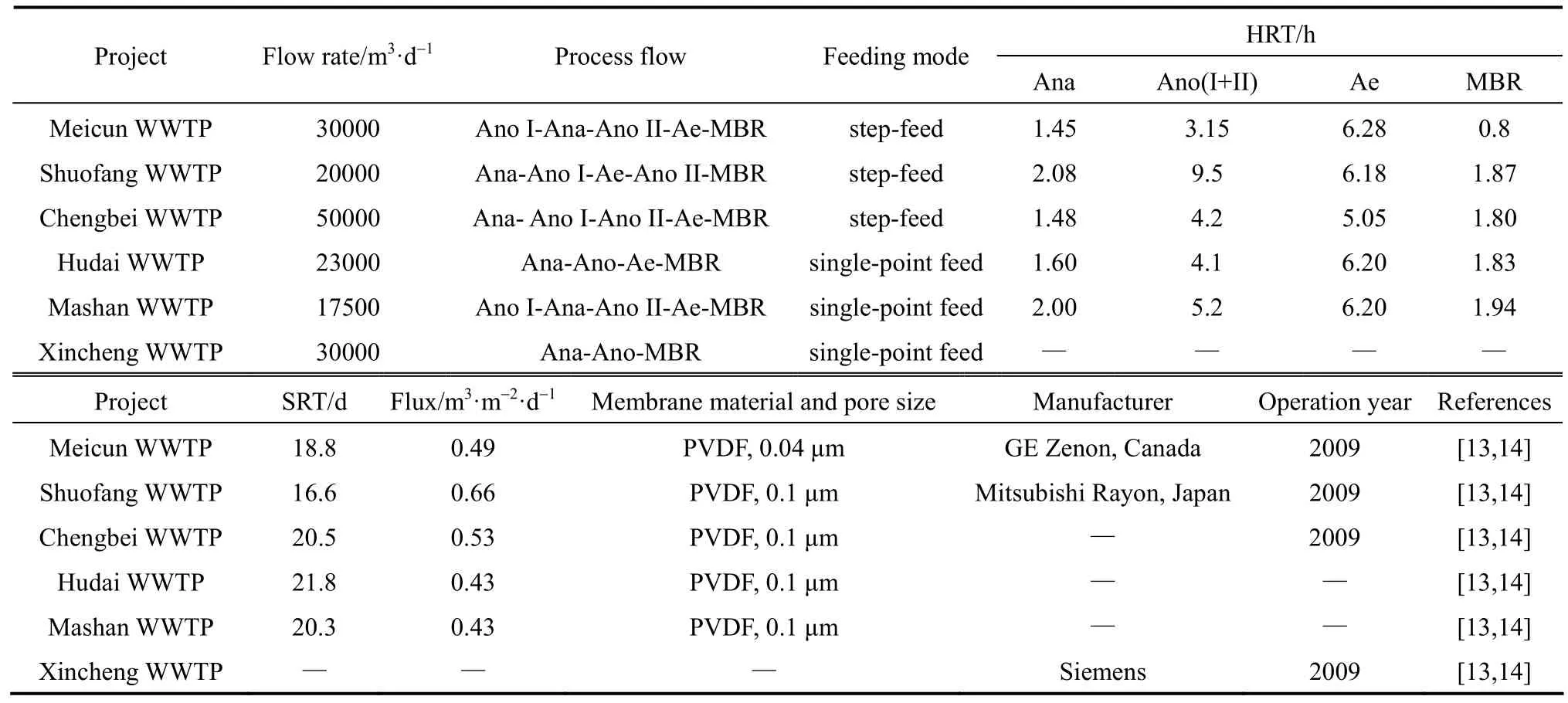

In recent years, the integration of BNR process with MBR as an efficient combined process has been used for the wastewater treatment to polish the quality of the effluent, including such BNR processes as UCT process, A/O process and A2O process [9-11]. It was reported that incorporating membranes into BNR activated sludge systems made a profound difference not only in the design of the BNR system but also in the operation for the whole WWTP [12]. The advantages of membrane process, such as more space saving and lower cost, make it practical as an attractive and competitiveremoval efficiencies, overtechnology for wastewater reuse, upgrading, and reconstruction of existing WWTPs. In China, about 20 MBR plants possessed the treatment capacity exceeding 1×104m3·d−1in 2008 [13]. Earlier in 2007, a large algal bloom in Taihu Lake in Southern China caused a severe deterioration of water quality, resulting in more stringent regulations and wastewater reuse standards. Thereafter MBR has been considered as an efficient solution to help restore the water quality and applied in the upgrading and reconstruction of the existing WWTPs around the Taihu Lake area. Table 1 represents the application of BNR-MBR process in the WWTPs in the southern Yangtze River region. A2O and its various modification processes have been used as the main BNR process combined with MBR in these plants. Few reports could be found on the performance of these full scale projects especially on the nutrient removal.

Table 1 Summary of MBR plants in Southern China

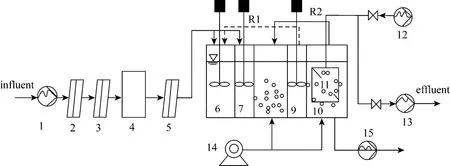

Figure 1 Schematic diagram of the full scale modified A2O-MBR plant1—influent pump; 2—first screen; 3—second screen; 4—aerated grit chamber; 5—fine screen; 6—anoxic reactor; 7—anaerobic reactor; 8—aerobic reactor; 9—pre-anoxic reactor; 10—membrane bioreactor; 11—hollow fiber membrane; 12—backwash pump; 13—permeate pump; 14—blower; 15—excess sludge pump; R1—recycle from pre-anoxic to anoxic reactor; R2—recycle from MBR to aerobic reactor

In this study, a full scale modified A2O (anoxic/ anaerobic/aerobic/pre-anoxic)-MBR plant (treatment capacity of 15000 m3·d−1) with the step feed operational strategy is operated to evaluate the performance of this integrated system on the nutrient removal from low C/N ratio municipal wastewater, aiming to provide practical and useful technical references for the upgrading and reconstruction of other sewage treatment plants.

2 MATERIALS AND METHODS

2.1 Full scale plant configuration and operation

The schematic diagram of the full scale modified A2O (anoxic/anaerobic/aerobic/pre-anoxic)-MBR plant is shown in Fig. 1. It consists of a pretreatment system and bio-treatment reactors with modified A2O configuration followed by an MBR. The raw municipal wastewater collected from the combined sewer system of the local district is pretreated via two stage screens, aerated grit chamber, and a third fine screen to preventlarge solids from entering the bio-treatment reactors or damaging the membranes. The bio-treatment reactors consist of two parallel compartments, each composed of a sequencing anoxic/anaerobic/aerobic/pre-anoxic reactor, providing alternating anoxic/anaerobic/aerobic conditions for the biological removal of nitrogen and phosphorus, and an MBR, in which a submerged hollow fiber membrane module is immersed. The pre-anoxic reactor in this system is to decrease the dissolved oxygen (DO) concentration of the aerobic effluent to below 0.5 mg·L−1. In this study, only one compartment of this plant was put into trial operation and investigated with the flow rate of 15000 m3·d−1.

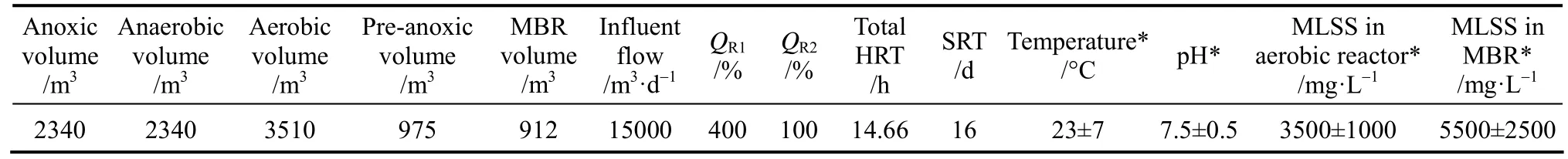

The effluent from the pretreatment system was fed into both anoxic and anaerobic zones using the step feed strategy (distribution ratio, 1︰1). In order to facilitate the nutrient removal, two different internal recycles (R1, R2) were provided, QR1was set at 400% of influent flow rate from pre-anoxic to anoxic and QR2was set at 100% of influent flow rate from MBR to aerobic. Anoxic and anaerobic zones were provided with a low speed mixer to keep the mixed liquor suspended solids (MLSS) in suspension. Diffusive oxygen emitters were equipped in the aerobic zone to ensure a sufficient oxygen supply (DO concentration above 2.5 mg·L−1) as well as to improve contact between microorganisms and wastewater. The solid-liquid separation occurred in MBR equipped with the submerged hollow fiber membrane (PVDF) with a nominal pore size of 0.075 μm (Saveyor, SVM-0680, Canpure Environment Protection Equipment Co., Ltd.). The membrane modules were symmetrically placed, and the total membrane area was 43200 m2in each compartment. The membrane was operated on a timer in such a way that in every 9 min the permeate discharge was stopped for 1 min for cleaning through air scouring, and the daily operating time of membrane was 23.6 h. Membrane fouling was reduced by introducing air at the bottom of the membrane module (scouring) as well as by the on-line backwashing with tap water. The sludge was wasted from MBR daily to maintain a relatively stable MLSS concentration and a desired solids retention time (SRT). The plant was provided with a programmable logic controller controlling all the automatic control loops of the plant. Detailed design and operational parameters of the plant are summarized in Table 2.

2.2 Influent wastewater characteristics

The full scale modified A2O-MBR plant is located at Binhu New District, Hefei City, Anhui Province, China. The major characteristics of the raw wastewater are listed in Table 3. The TCOD/TN ratio of raw influent was averaged at 3.78 with the lowest down to 1.73 during the experimental period, indicating the lack of available carbon source for nitrogen and phosphorus removal.

Based on the electron balance and the traditional theory of nitrogen removal, a theoretical C/N ratio of 2.86 g COD per gram N is needed to achieve complete denitrification. In practice, however, more COD will be consumed considering the growth of microorganisms. Additionally, the heterotrophic microorganisms responsible for the phosphorus removal also require carbon/energy sources, so a higher C/N ratio is required to achieve simultaneous removal of nitrogen and phosphorus. Since the C/N ratio of the raw municipal wastewater used for this study was low, the BNR would be limited by the lack of available organic carbon source. An external carbon source is a solution for increasing the substrate loading to improve the BNR efficiency, especially for the low C/N ratio wastewater treatment, so sodium acetate, a common carbon source with relatively high denitrification efficiency, was used in this study.

2.3 Start-up of the plant

A start-up period of 45 days (April 1st to May15th) was required for biomass acclimation and stable unit performance. The plant was inoculated with excess activated sludge from the Wangtang sewage treatment plant (Hefei City, China) where the oxidation ditch process was used with treatment capacity of 80000 m3·d−1. During the start-up period, the influent flow rate increased gradually from 5000 to 15000 m3·d−1. No sludge was discharged except for the sampling to maintain the biomass. Once the MLSS concentration in aerobic reactor reached 3000 mg·L−1, the performance of the plant was evaluated from May 16th, 2011. This study was divided into two phases. Phase 1 was operated without the addition of external carbon source while Phase 2 was operated with sodium acetate (CH3COONa·3H2O, 58%-60%) as an external carbon source added to the anoxic zone at 500 kg·d−1, i.e., a theoretical increase of 31.3 mg COD per liter in influent into the anoxic zone, similar to the values used in previous studies [15].

Table 2 Design and operational parameters of the plant

Table 3 Major characteristics of the raw influent

2.4 Analytical methods

Samples were collected regularly from different locations of the plant as well as influent and effluent for the measurements of COD, BOD5MLSS,4NH-N+,dard Methods [16]. Influent flow rate, effluent flow rate, trans-membrane pressure (TMP) drop, DO, oxidation-reduction potential, pH, and temperature were monitored continuously by the online real-time systems.

3 RESULTS AND DISCUSSION

3.1 Organics and SS removal

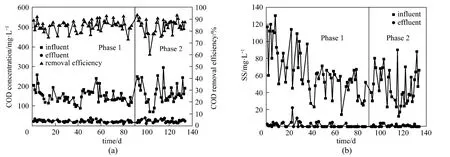

Figure 2 shows the system COD and SS removal during the whole operation. Although the influent COD concentration varied from 70 mg·L−1to 295 mg·L−1, a stable low COD level below 30 mg·L−1in effluent was obtained [Fig. 2 (a)]. The addition of external carbon source does not present any significant effect on the effluent COD concentration in Phase 2. The effluent SS concentration approached almost zero (below detection limit) for both phases, showing a good performance of solid-liquid separation in the MBR [Fig. 2 (b)].

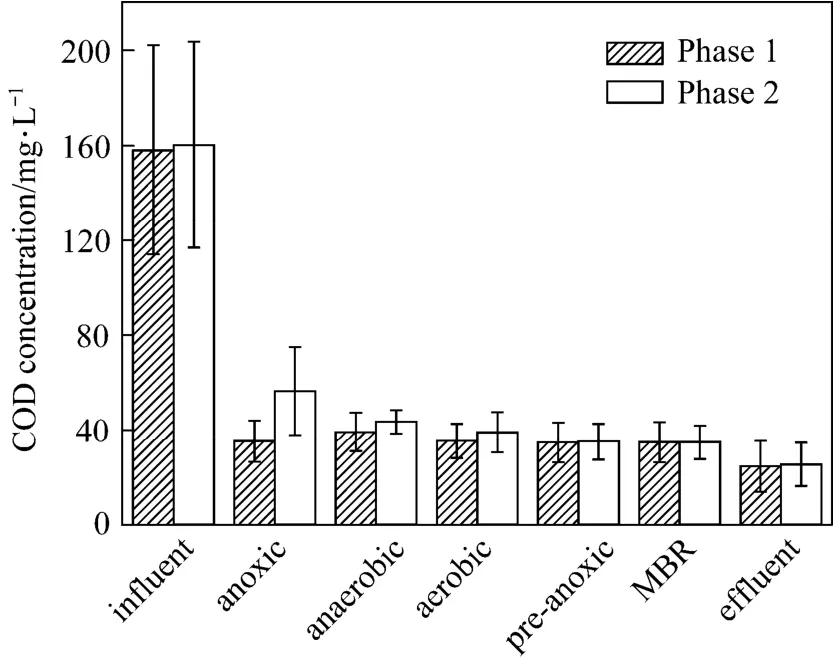

Figure 3 depicts the transformation of COD in the system. It is noteworthy that the COD distribution among reactors is relatively uniform, probably due tothe dilution from the nitrified liquid recycling to anoxic zone. The addition of external carbon does not cause significant difference in COD concentration expect in anoxic zone compared with the results from Phase 1. The major part of influent COD is consumed in the modified A2O reactors, and the MBR is beneficial for lower and much more stable COD effluent. During Phase 1, for example, the average COD removal efficiency at the end of pre-anoxic zone was 78.0%, while it increased to 84.5% after the membrane modules, i.e., 6.5% contribution of the membrane filtration to the COD removal. It was reported that 4.5% contribution of the membrane filtration to the COD removal efficiency was obtained in the integrated MUCT-MBR system, and different C/N ratios did not have influence on COD removal [17]. Results from Wang et al. [18] further confirmed that MBR has a strong capability of anti-shock COD loading. These findings coincide with the results of this study. Thus it can be concluded that the COD removal is mainly due to the biological degradation in the modified A2O zone rather than the membrane separation, while membrane filtration is very beneficial to keep a higher COD removal efficiency.

Figure 2 COD (a) and SS (b) removal at different phases

Figure 3 Transformation of COD in the modified A2O-MBR system in two phases (n=7)

3.2 Nitrogen removal

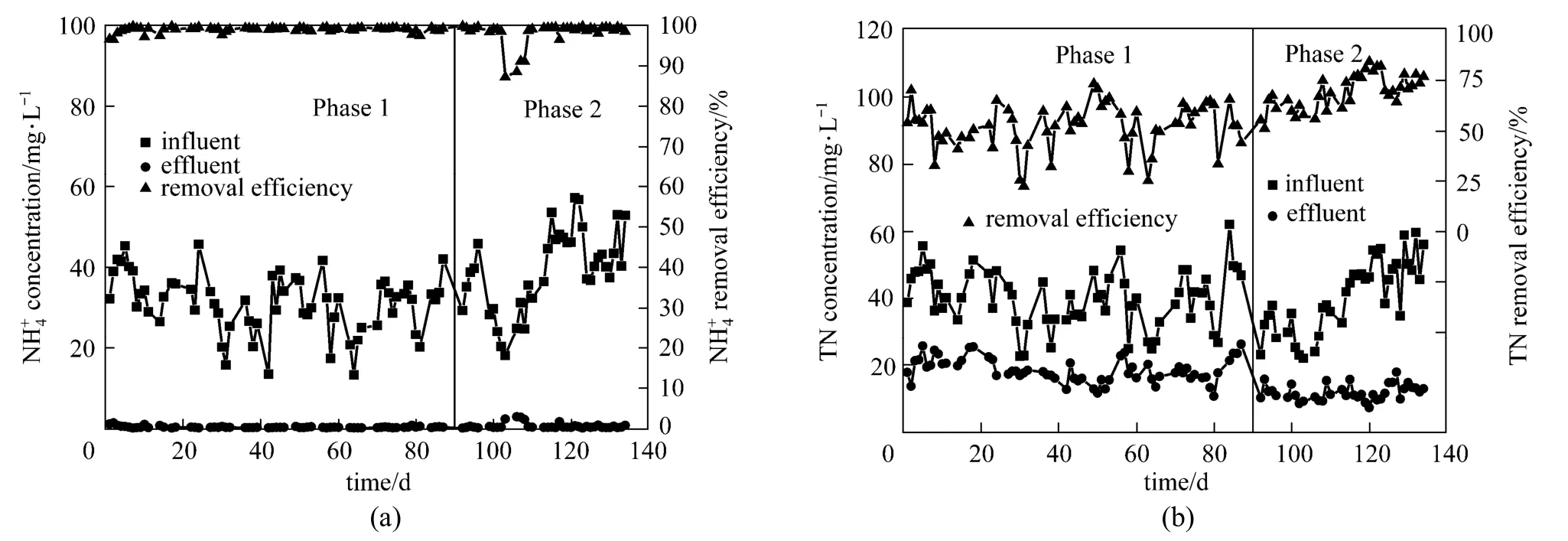

The performance of nitrogen transformation in the whole system is shown in Fig. 5. The influentconcentration accounted for about 80% of the influent TN [Fig. 5 (a)], and theconcentration dropped significantly (from 28.00 mg·L to 5.18 mg·L−1) in the anoxic reactor due to the dilution effect of the recirculation. TN was mainly removed in the anoxic reactor and decreased to about 20 mg·L−1.

Figure 4 4NHN+-(a) and TN (b) removal at different phases

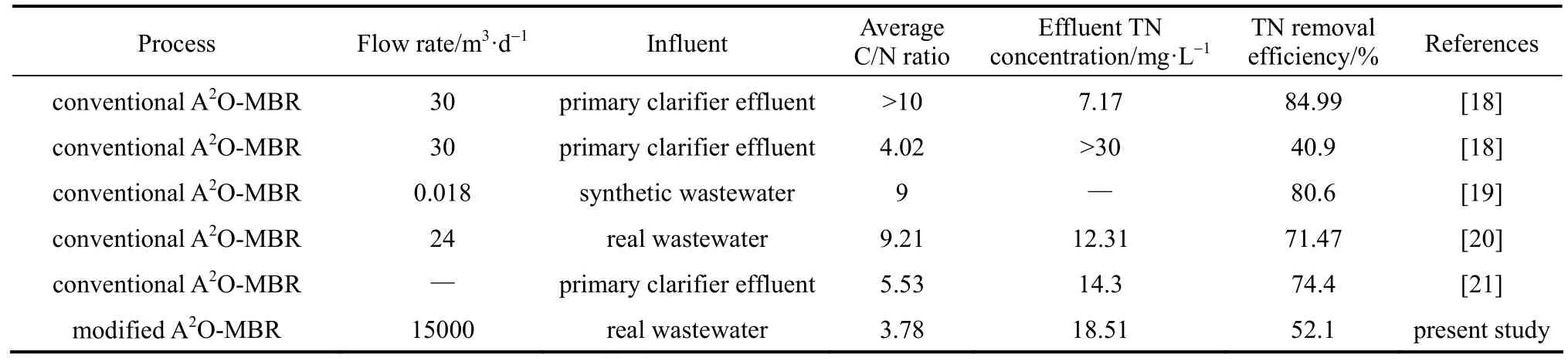

Table 4 Comparison of TN removal in conventional A2O-MBR process in literature

Figure 5 Typical transformation of nitrogen in the modified A2O-MBR system in Phase 1 (a) and Phase 2 (b) (n=7)

Figure 6 TP removal at different phases

In the aerobic reactor,4NH-N+was converted to

3 NO-N−and, the average4NH-N+removal efficiency was over 90%. This implied that sufficient nitrifying bacteria were presented in the aerobic reactor and complete nitrification occurred. However, it should be noted that the effluent3NO-N−concentration accounted for 82% of the effluent TN during Phase 1, suggesting incomplete denitrification due to the lack of electron donor. As shown in Fig. 5 (b), the trend of nitrogen transformation after the addition of external carbon source was similar to that without the addition of carbon source in Phase 1. On the other hand, the TN concentration in anoxic zone was significantly decreased to about 15 mg·L−1, increasing TN removal efficiency from 52.1% to 74.9%.

3.3 Phosphorus removal

The TP removal in the system is shown in Fig. 6. The influent TP concentration fluctuated dramatically from 1.68 mg·L−1to 6.59 mg·L−1, and the removal efficiencies in Phases 1 and 2 were 25.5% and 43.5%, respectively. The effluent TP concentration was about 1 mg·L−1with the removal efficiency close to 63.0% on the initial days (92-109 d) of Phase 2. One possiblereason for such temporary TP removal improvement was that the external carbon source might not be fully utilized by the denitrifiers (in agreement with the relatively low TN removal efficiency of 60.28%) and provided some additional carbon source for the phosphate release in anaerobic zone. Thereafter, more carbon source was consumed for the enrichment of denitrifying bacteria and less carbon source flowed into the anaerobic reactor, subsequently decreasing TP removal and increasing effluent TP concentration.

Several significant reasons could be taken into consideration for the mediocre phosphorus removal performance in this system. Firstly, the high nitrate concentration resulted from the incomplete denitrification might limit phosphate release in the anaerobic reactor and subsequently negatively affected phosphate uptake in the aerobic or anoxic reactor. Secondly, the COD/P ratio higher than 40 is considered a rough estimate for good phosphorus removal [22], although 50% of influent carbon source was directly utilized in the anaerobic zone by incorporating the step feed strategy to enhance the biological phosphorus removal in this plant, a shortage of carbon source still limited the phosphorus release in anaerobic reactor. Thirdly, the long SRT (16 d) might also limit the phosphate incorporation into new cell materials. Therefore, it can be inferred that the biological phosphorus removal would be probably influenced when taking biological nitrogen removal into the first consideration.

3.4 Membrane fouling

The TMP in MBR was monitored continuously to evaluate the membrane fouling during the whole operation period, and the value was in the range of 1-38 kPa and the flux was 6.3-14.6 L·m−2·h−1(LMH). The TMP was shown closely related to the degree of membrane fouling under the operational condition of invariable hydraulic retention time (HRT) [23], and the MLSS concentration was an important factor affecting membrane fouling directly [24]. Fig. 7 shows the variation of TMP, LMH and MLSS concentration during the study period. The MLSS concentration initially increased from 4500 mg·L−1to nearly 8000 mg·L−1on day 38 and was maintained for about 15 days. During this period, the TMP increased linearly. On day 78, with the air flow rate raised by 20% from 0.133 (m3·m−2·h−1) to 0.178 (m3·m−2·h−1), the TMP was alleviated with a decrease of 6.5 kPa. This alleviation of membrane fouling was due to the shear stress strengthened on the membrane surface and the air scrubbing as the effective mechanical cleaning for removing the deposited particles on the membrane [25]. However, this scouring effect was temporary, and the TMP started to increase again from 17.9 kPa on day 83 to 38.1 kPa on day 117, so the on-line chemical cleaning was applied using sodium hypochlorite (NaClO) at 2000 mg·L−1and the TMP was recovered to a lower value (31.2 kPa). The off-line chemical cleaning was not performed during the entire operational period. The membrane fouling could be alleviated to a certain degree by both air scrubbing and on-line chemical cleaning.

4 CONCLUSIONS

This full scale study was on the simultaneous removal of organics, nitrogen, and phosphorus in a modified A2O-MBR system coupled with the step feed strategy. Results showed that the modified biosystem achieved good COD and4NH-N+removal efficiencies, more than 84.5% and 98.1%, respectively, regardless of the presence of external carbon source. SS was almost completely removed as well. A relatively good TN removal efficiency of 52.1% was obtained without the addition of any external carbon source and this might be attributed to the reversion of anoxic and anaerobic zones along with the step feed strategy. The addition of external carbon source into the anoxic zone with a theoretical amount of 31.3 mg COD per liter in influent further increased both TN and TP removal significantly. The TN removal efficiency increased from 52.1% to 74.9%, with the effluent concentration almost lower than 15 mg·L−1, and the TPremoval efficiency increased from 25.5% to 43.5%. The system did not present a satisfactory performance in the phosphorus removal, so other phosphorus removal alternatives such as chemical phosphorus removal need to be complemented. The results obtained in this study indicate that the modified A2O-MBR process is able to improve the BNR performance in treating low C/N ratio municipal wastewater, and the addition of external carbon source may serve as a suitable optimization method to improve process performance.

Figure 7 MLSS (a), LMH and TMP (b) concentration during the operational period

REFERENCES

1 Tchobanologous, V.G., Burton, F.L., David, H., Wastewater Engineering: Treatment and Reuse, 4th Ed., McGraw Hill publication, New York, USA (2003).

2 Lee, J., Kim, J., Lee, C., Yun, Z., Choi, E., “Biological phosphorus and nitrogen removal with biological aerated filter using denitrifying phosphorus accumulating organism”, Water Sci. Technol., 52 (10/11), 569-578 (2005).

3 Fu, G., Dong, B., Zhou, Z.Y., Gao, T.Y., “Design characteristics and operating parameters of inverted AAO process”, Water & Wastewater, 20 (9), 53-55 (2004). (in Chinese).

4 Bi, X.J., Gao, T.Y., “Study on anoxic/anaerobic/aerobic process of denitrification and phosphorus removal”, Shanghai Environmental Sciences, 18 (1), 19-21 (1999). (in Chinese)

5 Zhang, B., Gao, T.Y., “Principle and characteristics of reversed A2/O process”, Water & Wastewater, 16 (7), 11-15 (2000). (in Chinese).

6 Vaiopoulou, E., Melidi, P., Aivasidis, A., “An activated sludge treatment plant for integrated removal of carbon, nitrogen and phosphorus”, Desalination, 211, 192-199 (2007).

7 Vaiopoulou, E., Aivasidis, A., “A modified UCT method for biological nutrient removal: Configuration and performance”, Chemosphere, 72, 1062-1068 (2008).

8 Zhu, G.B., Peng, Y.Z., Wang, S.S., Wu, S.Y., Ma, B., “Effect of influent flow rate distribution on the performance of step-feed biological nitrogen removal process”, Chem. Eng., 131, 319-328 (2007).

9 Lee, H., Han, J., Yun, Z., “Biological nitrogen and phosphorus removal in UCT-type MBR process”, Water Sci. Technol., 59 (11), 2093-2099 (2009).

10 Fu, Z.M., Yang, F.L., An, Y.Y., Xue, Y., “Simultaneous nitrification and denitrification coupled with phosphorus removal in a modified anoxic/oxic-membrane bioreactor (A/O-MBR)”, Biochem. Eng. J., 43, 191-196 (2009).

11 Banu, J.R., Uan, D.K., Yeom, I.T., “Nutrient removal in an A2O-MBR reactor with sludge reduction”, Bioresour. Technol., 100, 3820-3824 (2009).

12 Ramphao, M., Wentzel, M.C., Merritt, R., Ekamma, G.A., Young, T., Buckley, C.A., “Impact of membrane solid-liquid separation on design of biological nutrient removal activated sludge system”, Biotechnol. Bioeng, 86 (6), 630-646 (2005).

13 Zhou, Y.F., Yu, M., Yang, Y., Zheng, X., “Application and market prospect of membrane bioreactors in China”, Industrial Wastewater Treatment, 30 (7), 5-7 (2010). (in Chinese)

14 Jiang, L.L., Hu, B., Zhang, W.L., Liu, J., Chen, Q.P., “Application of MBR technology in the wastewater treatment plants in Taihu Lake basin”, Water & Wastewater, 37 (1), 14-18 (2011). (in Chinese)

15 Yang, M., Sun, Y.L., Zheng, X.C., Li, P.F., “Denitrification efficiency and techno-economic analysis of different exotic additional carbon source”, Water & Wastewater, 36 (11), 125-128 (2010). (in Chinese)

16 American Public Health Association (APHA), American Water Works Association (AWWA), Water Environment Federation (WEF), Standard Methods for the Examination of Water and Wastewater, 20th Ed., Washington DC, USA (1998).

17 Zhang, H.M., Wang, X.L., Xiao, J.N., Yang, F.L., Zhang, J., “Enhanced biological nutrient removal using MUCT-MBR system”, Bioresour. Technol., 100, 1048-1054 (2009).

18 Wang, Z.Z., Li, J., Gao, J.H., Chang, J., “Anti-shock loading performance of A2O/MBR and optimization of nitrogen and phosphorus removal”, Water & Wastewater, 26 (21), 38-42 (2010). (in Chinese)

19 Zhang, H.M., Zhang, J., Xiao, J.N., Yang, F.L., “Study on the enhanced biological nitrogen and phosphorus removal via dinitrification of A2/O-MBR process”, Journal of Dalian University of Technology, 48 (4), 490-495 (2008). (in Chinese)

20 Zhu, N.W., Li, J., Zheng, X.Y., Yang, P.C., Chen, H., Wu, D., “Combined process of A2/O and MBR for treatment of municipal wastewater”, China Water & Wastewater, 26 (15), 1-4 (2010). (in Chinese)

21 Cao, B., Huang, X., Kitanaka, A., Yang, Y.F., Yang, D.L., “Pilot test on enhanced biological nitrogen and phosphorus removal by using A2/O-MBR”, China Water & Wastewater, 23 (3), 22-26 (2007). (in Chinese)

22 Toit, G., Ramphao, M.C., Parco, V., Wentzel, M.C., Ekama, G.A.,“Design and performance of BNR activated sludge systems with flat sheet membranes for solid-liquid separation”, Water Sci. Technol., 56 (2), 105-113 (2007).

23 Barnard, J.L., Abraham, K., “Key features of successful BNR operation”, Water Sci. Technol., 53 (12), 1-9 (2006).

24 Kim, J.Y., Chang, I.S., Shin, D.H., Park, H.H., “Membrane fouling control through the change of the depth of a membrane module in a submerged membrane bioreactor for advanced wastewater treatment”, Desalination, 231, 35-43 (2008).

25 Kim, H.S., Seo, I.S., Kim, Y.K., Kim, J.Y., Ahn, H.W., Kim, I.S.,“Full-scale study on dynamic state membrane bio-reactor with modified intermittent aeration”, Desalination, 202, 99-105 (2007).

2012-10-06, accepted 2013-04-12.

* Supported by the National Water Pollution Control and Management (2008ZX07316-002) and the University of Macau Research Committee (RG067/09-10S/SHJ/FST).

** To whom correspondence should be addressed. E-mail: sally_xieli@yahoo.cn

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- An Approach to Formulation of FNLP with Complex Piecewise Linear Membership Functions

- Determination and Correlation of Solubility for D-Xylose in Volatile Fatty Acid Solvents*

- Impacts of Power Density on Heavy Metal Release During Ultrasonic Sludge Treatment Process*

- One Step Preparation of Sulfonated Solid Catalyst and Its Effect in Esterification Reaction*

- Effects of Assistant Solvents and Mixing Intensity on the Bromination Process of Butyl Rubber*

- Determination and Correlation of Solubilities of Four Novel Benzothiazolium Ionic Liquids with6PF−in Six Alcohols*