Towards Domain boundary engineering:Twinning in Strained Ferroelastics

2013-11-08刘刚

The generation of functional interfaces such as superconducting and ferroelectric twin boundaries requires new ways to nucleate as many interfaces as possible in bulk materials and thin films.Materials with high densities of twin boundaries are often ferroelastics and martensites.Researchers in State Key Laboratory for Mechanical Behavior of Materials,Xi’an Jiaotong University found that(X.Ding,Z.Zhao,T.Looman,A.Saxena,E.Salje,Advanced Materials,2012,24:5 385 -5 389)a shear on ferroelastic single crystals will lead to the spontaneous nucleation of crystals with complex domain structures once the yield strain is overcome.The“volume”contribution of domain boundaries was estimated from computer simulations of a simple two-dimensional model to be ca.5%of the total bulk material and is higher than in quenched materials.The observed trend is that the number of junctions between twin boundaries is found to be very high(about 0.2%of the number of bulk atoms)when the underlying elastic bulk moduli are soft but much lower in hard materials(Fig.1).The microstructures,as generated by isothermal strain,show a very high wall and junction contribution which makes them suitable as functional materials where the functionality stems from the interfacial properties and not from the bulk.

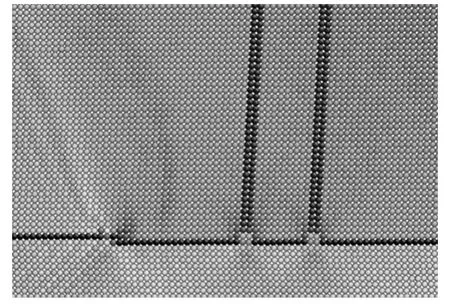

Based on the above results,the same group further studied the Mechanical Loss in Multiferroic Materials at High Frequencies.The development of novel multiferroic device materials has hit a fundamental limitation when the driving frequency is increased beyond 50 MHz.Ultimately people want to use detectors,memory chips and converters between electric and magnetic signals at such high frequencies.The idea is hence that device materials need to be defect free because any extrinsic defect relaxation will be slower than the operating frequency and will hence absorb the external signal.The solution of this conundrum was to use very clean multiferroic materials where the desired change of electric and magnetic dipoles is very fast in thin films.The group in Xi’an Jiaotong university found that this solution does not work in most materials where coupling to ferroelasticity is strong(Z.Zhao,X.Ding,T.Lookman,J.Sun,and E.K.H.Salje,Advanced Materials,2013,DOI:10.1002/adma.201300655).They demonstrated that only two mechanisms dominate the mechanical loss in perfect clean materials,namely,the propagation of needle domains and the movements of wall kinks(Fig.2).No extrinsic defects are required for the mechianical absorption so that future works on novel multiferroic devices need to carefully avoid the change of ferrealstic domain structure under dynamic driving condition.

Fig.1 Junction density for hard(full circles)and soft(open circles)thin materials with a steep increase of the density for small systems sizes for soft materials.Hard materials have strong correlations between the twin walls and junctions which prevents the nucleation of junctions for small system sizes.This means that twin walls are parallel with little interaction between them.In soft layers,the strain energy related to junctions is smaller so that intersections between twin walls are common and lead to higher junction densities for small system sizes

Fig.2 Computer simulations of a single two-dimensional model on a generic,proper ferroelastic material show that energy absorption in multiferroic materials stems typically from strain relaxation which can be strong even in clean materials.The dissipative mechanisms associated with the dynamical motion arise from the advance and retraction of needle domains and movement of kinks inside twin boundaries