Numerical study of the effect of flow rate and temperature on parison swell and sag in extrusion

2013-11-05PENGJiong彭炯LIJing李静CHENJinnan陈晋南LIUShali刘沙粒

PENG Jiong(彭炯), LI Jing(李静), CHEN Jin-nan(陈晋南), LIU Sha-li(刘沙粒)

(School of Chemical Engineering and Environment,Beijing Institute of Technology,Beijing 100081,China)

The degree of the extrusion swell and parison sag depends on the flow rate,melt temperature,geometric of the die,rheological parameter of the melt and so on[1].Combined effect of extrusion swell and parison sag acts on the parison,which makes the design of the die and extrusion molding process very complex.In recent years,numerical simulation has become an important tool to predict parison formation. In 2003, Huang et al.[2]studied the diameter swell and sag of the high density polyethylene(HDPE)/PA6 parison.He analysed the experimental data using a neural network approach and presented the model of the diameter swell profile.In 2007,Evan[3]studied the effects of weak compressibility and linear slip condition using the finite element method.He indicated that weak compressibility slightly affects the thickness swell,but slip drastically reduces the swelling to 1% -2% forobviousslip.Evan[4]also studied the ring extrusion swell of the pseudoplastic fluid and viscoplastic fluid,and compared the extrusion swell of two kinds of fluids.In 2009,Yousefi et al.[5]studied the effect of rheological properties of HDPE on the parison formation in extrusion blow molding by experiments and numerical simulation.In 2011,Li et al.[7]simulated three-dimensionalslitflows in extrusion sheet dies using the constitutive equations of Carreau-Yasuda and PTT with a finite piece method.

In this paper,the distributions of the velocity,shear rate,viscosity,pressure,thickness in the real flow domain of a common die of the blow molding were simulated.The influences of the flow rate and temperature on extrusion swell and parison sag were studied.

1 Mathematical and physical models

According to the characteristics of the polymer melts flown in a die and melts formed the parison,the following assumptions were made in the numerical simulations,① the HDPE melt is an incompressible fluid;②the flow in the die channel and the parison is laminar,and isothermal;③the die is always full of the polymer melt.Based on these assumptions,the equations of continuity and motion can be reduced to Δ

where η is the shear viscosity;η0is the zero shear viscosity;λ is the relaxation time;n is the non-Newtonian index. The polymer melt is HDPE,with the density of 960 kg/m3.Rheological parameters of Carreau model at different temperatures are shown in Tab.1.

Tab.1 Rheological parameters of HDPE under different temperatures

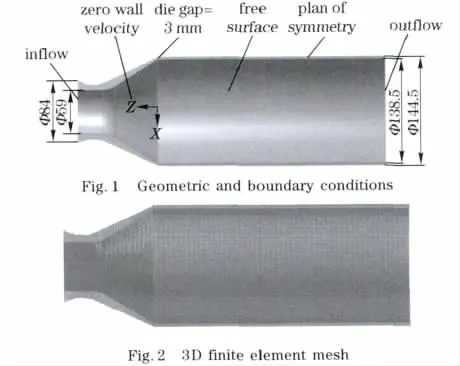

Fig.1 shows geometries of the die and the main boundary conditions.The mini-element method is used in velocities interpolation,and Picard iteration is used to solve nonlinear equations by polyflow.The elements of the die and the parison were 70 452,as shown in Fig.2.The simulations were conducted on a Hewlett-Packard XW9300 workstation.It took approximately 3 h to obtain a converged solution with a relative error smaller than 0.1% in all of the field variables.

2 Results and discussion

2.1 Influence of the flow rate

If the flow rate is too high,the melt flow exiting the die will be unstable,which causes the surface of the parison to be rough. Therefore,study on the extrusion swell and parison sag at different flow rates is important.Flow fieldsof HDPE melt for volumetric flow rates of 3.0×10-6,4.0 ×10-6,5.0 ×10-6and 6.0 × 10-6m3/s were calculated at temperature of 180°.The average pressure of the polymer in the die along the negative Z axis under different volumetric flow rates is shown in Fig.3.The pressure decreases along the negative Z axis and increases with increasing flow rate.When the volumetric flow rate increases from 3.0×10-6to 6.0×10-6m3/s,the maximum of the pressure increases from 1.25 to 2.00 MPa.From Fig.4,the average velocity of the parison decreases due to extrusion swell at the top of the parison.The polymer melt is accelerated by gravity along the negative Z axis and the maximum velocity of the melt appears at the bottom of the parison,which means that the minimum velocity appears at the top of the parison.As shown in Fig.5a,an increase in flow rate can cause the extrusion thickness swell to increase.The thickness increases at the top of the parison,but decreases at most of the parison.The maximum thickness appears at the top of the pari-son due to extrusion swell,however the minimum thickness appears at the bottom of the parison due to gravity.The maxmum thickness is 4.1 ×10-3m under a flow rate of 6.0 ×10-6m3/s,which is increased by 36.67% .As shown in Fig.5b,the contraction of parison decreases at the bottom of the parison with the increasing flow rate.The minimum of the radius is 4.5×10-2m,which is decreased by 37.93%.

2.2 Influence of the temperature

In order to investigate the effect of temperature,the HDPE flow fields of velocity,pressure,thickness and radius are discussed under qv=6.0×10-6m3/s and at different temperatures of 170,180,190,200,and 210℃.

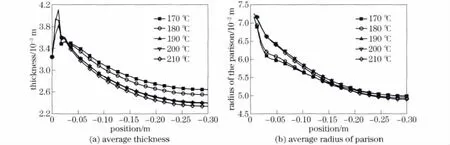

Fig.5 Average thickness and radius of the parison along negative Z axis at 180℃

In Fig.6a,the viscosity of the polymer melt decreases with increasing temperature.As shown in Fig.6b,the velocity of the parison increases as the temperature increases,which is caused by the decrease of the viscosity.It means that the viscosity of the polymer melt decreases due to increased temperature,enhancing its liquidity.As shown in Fig.7a,the effect of parison thickness swell decreases with increasing temperature.The maximum thickness at 210℃ is 3.8×10-3m.Compared with 180℃,the thickness has a decrease of 3 ×10-4m .As shown in Fig.7b,at the top of the parison,the radius increases with an increase in temperature,while at the bottom of the parison,the radius of the parison decreases with an increase in temperature.From Fig.5 and Fig.7,swell of thickness and radius are more sensitive to flow rate than to temperature.

Fig.6 HDPE flow field field under different temperatures and qv

Fig.7 Average thickness and radius of the parison along negative Z axis at qv

3 Conclusions

Flow rate and temperature are two important factors that affect extrusion swell and parison sag.The mechanism of the combined effect of extrusion swell and parison sag is complex.Numerical simulation method can save costs and improve efficiency.In this paper,the degree of the swell and sag is described by thickness distribution and radius distribution,which is clear and simple.The results show that,① The thickness of the parison increases with increasing flow rate;②The radius at the end of the parison is smaller at smaller flow rate;③The radius decreases along the negative Z axis due to gravity;④Viscosity of the parison decreases with increasing temperature;⑤At the top of the parison,the radius increases with increasing temperature,while at the bottom of the parison the radius of the parison decreases with increasing temperature;⑥Swell thickness and radius are more sensitive to flow rate than to temperature.

[1] Yousefi A M,Collins P,Chang S,et al.A comprehensive experimental study and numerical modeling of parison formation in extrusion blow molding[J].Polymer Engineering and Science,2007,47(1):1-13.

[2] Huang H X,Liao C M.HDPE/PA6 blends:parison formation behavior in extrusion blow molding[J].Polymer Testing,2003,2(5):509 -513.

[3] Mitsoulis E.Annular extrudate swell of newtonian fluids:effects of compressibility and slip at the wall[J].Journal of Fluids Engineering,2007,129(11):1384-1393.

[4] Mitsoulis E.Annular extrudate swell of pseudoplastic and viscoplastic fluids[J].Journal of Non-Newtonian Fluid Mechnics,2007,141(2-3):138-147.

[5] Yousefi A M,Doelder J,Rainville M A.A modeling approach to the effect of resin characteristics on parison formation in extrusion blow molding[J].Polymer Engineering and Science,2009,49(2):251-263.

[6] Li Y,Zheng J R,Xia C M,et al.A finite piece method for simulating polymer melt flows in extrusion sheet dies[J].Journal of Applied Polymer Science,2011,123(6):3189-3198.