电控发动机故障诊断专家系统设计

2013-08-22张忠洋辽宁工业大学汽车与交通工程学院辽宁锦州121001

魏 丹,张忠洋辽宁工业大学汽车与交通工程学院,辽宁锦州 121001

1.Introduction

Along with the enhance of the automobile technology,the automobile structure and function are complex and perfect day by day,especially the computer and the control science applied widely on automobile,it improved the dynamics,the economy and the emissions etc.of the automobile[1].Electronic control technology makes the automobile as high-tech products with mechanical,electrical and fluid,but it needs higher requirements for the technology of automobile fault diagnosis and maintenance,the configuration of maintenance hardware and software and the maintenance personnel technical level,so it urgent need an intelligent system which can guide automobile maintenance to locate the fault parts,find out the causes of the faults and give maintenance proposal.Sharing the service information of auto fault diagnosis through the internet,it not only can provide premium services for users,but also can reduce expenses and costs for automobile manufacturers and automobile maintenance business[2].Therefore,this paper designed the expert system of electronic control engine fault diagnosis based on B/S,which applying the technology of fault tree diagnosis,and realizing rapid,accurate and intelligent diagnosis for common faults of electronic control engine[3].

2.The system total design

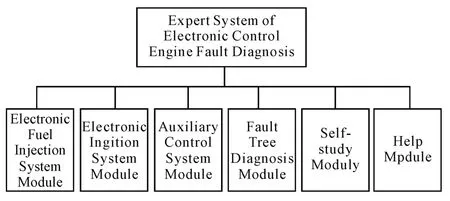

The expert system of electronic control fault diagnosis based on WEB includes the following modules,shown in Fig.1:

Fig.1 The overall structrue of expert system of engine fault diagnosis

1)Electronic fuel injection system module

The main function of the module is to store the diagnosis information,faults information,maintenance methods etc.of all operating conditions of all kinds of electronic fuel injection(EFI).On one hand it can help users to study the maintenance and diagnosis knowledge of EFI.On the other hand,users or manufacturers can input the information of the new production of EFI into the expert system,which can help users to maintain the new products,removal of faults.

2)Electronic ignition system module

The main function of the module is also to store the diagnosis information,the fault information,the maintenance methods etc.of all operating conditions of all kinds of electronic ignition system,and add new production information of electronic ignition system.

3)Auxiliary control system module

Auxiliary control system includes idle speed control system,intake air control system,pressure control system,emission control system,cruise control and electronic throttle system,cooling fan and generator control system and so on.The function of the module is also to store the diagnosis information,fault information,maintenance methods etc.of all operating conditions of above systems.

4)Fault tree diagnosis module

The main function of the module is to realize diagnosing the common faults of electronic control engine by combining the fault tree theory with the fault diagnosis technology[4-5].It is no need to study algorithms and rules by applying fault tree to process information,which can reduce software work greatly.Fault tree diagnosis system has strong abilities of knowledge acquisition,adaptive and self-learning.It also has better compatibility and quickly response.Therefore,the fault tree diagnosis system can overcome the difficulties of knowledge acquisition,matching conflict, combinatorial explosion, inference speed slow etc.which are exist in traditional expert system.

5)Self-study module

The module is mainly to realize self-study function for fault diagnosis.The self-study of expert system could adjust the knowledge rules of fault tree between parent slot and sub slot of learning reference module by training samples,to approach functional relations which the samples determined.

6)Help module

The module can provide users instruction of the system and help information.

3.Development environment and tools

The system uses development technology of B/S structure,which is a new structure aiming at the system defects of the original C/S structure[6].It is based on server development and use browser to access the system as client,and it greatly simplified the client computer loads,reduced the cost and effort of system maintenance and upgrades,and reduced the overall cost of the user.

The system using the popular technical solution of IIS+ASP+SQL-Server combined with Web server application in the Windows environment,which is invented by Microsoft.The solution provide an effective mean for develop dynamic,interactive and efficient Web management system.The system use.NET as the platform,and use Visual C#language to develop.Visual C#.NET which can develop application system more effective is come from Visual C++,it inherited all advantages of Visual C++,enhanced itself functions according to .NET strategy,and abandoned the insecurity factor of Visual C++.

4.The fault tree diagnosis of expert system

4.1.The basic theory of fault tree analysis

Fault tree model is a qualitative causal model to describe the object structure,functions and relationships,which reflects the level of fault propagation and child nodes(the lower fault source),and the parent node(the upper symptoms)between the causal relationship.Fault tree analysis is a graphical interpretation analysis of top-down layer by layer,the main purpose of the qualitative analysis is to identify the incident led to the top of all the possible failure modes,namely that finding all minimal cut sets of the fault tree.Minimum cut sets can be judged by the weakest link in the system,specifying the source and cause of the malfunction failure,and provide recommendations to improve programs and maintenance.

The structure function based on fault tree analysis is defined as follows:Let the fault tree(FT)in n-base events x1,x2,…,xn,C ∈{xi,…,xl}is a collection of some of the end of the event,when of which all the end events occur,the top event must occur,C called one of the fault tree cut sets.If C is a cut set,remove any one of the end event,it is no longer a cut set,then C is called minimal cut sets.If FT has k minimal cut sets,as long as all end events of one cut set Kj(j=1,2,…,k)occurred,the fault will occur,Kjcan be expressed as:.As long as there is one set cuts occur in K minimum cuts,the top event occur,so the structure function FT can be expressed as: φ

4.2.The implementation of fault tree analysis diagnosis expert system

1)The relation of fault tree analysis and rulebased expert system

Fault tree is a graphical fault model for system reliability analysis and fault diagnosis.The rulebased diagnostic expert system is to infer the location and cause of the malfunction and finally made troubleshooting methods and maintenance recommendations,when the fault of the system occurs,utilization various diagnostic information,according to the rules in the knowledge base,through reasoning to determine the system’s failure modes.

From the perspective of knowledge acquisition,the fault tree has a standardized knowledge structure.If generated the expert system knowledge base by the knowledge of the fault tree,the system can display to express problem-solving strategies of diagnostic experts,which can largely reduce the difficulty of the system knowledge acquisition,solving the bottleneck problem of rule-based expert system knowledge acquisition.

2)Diagnostic knowledge structure

Actually,the design of knowledge base of expert system based on fault tree is convert the fault tree form into database form,and get the rules from the data table.Because EFI engine failure modes and causes are complex,one data table is not enough in building knowledge base,so the system designed three associated tables that are fault tree table,rules parameter table and diagnostic conclusions table.The three tables take the fault tree as the contact entrance and take the fault phenomenon as the key words on the knowledge inquiry,determine corresponding trouble shooting method by rule finally.

3)Knowledge representation

The integration of knowledge representation based on the framework and rules of the fault tree is convert the fault tree into the most simple fault tree by qualitative analysis of fault tree,then convert the simple fault tree into one more production rules in knowledge base.Fault tree in which the logic“And gate”is equivalent to a rule;logic“Or gate”is equivalent to more than one rule.All diagnostic information and conversion of all production rules about fault tree are encapsulated in one framework,which has good scalability,easy to separate knowledge base and inference engine.

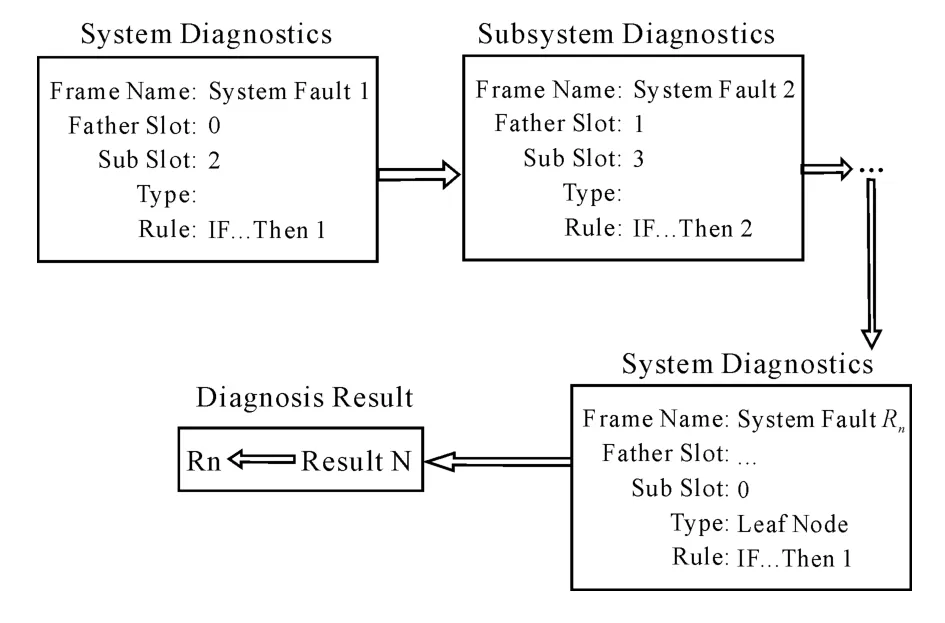

The knowledge of the framework include:Frame name–the description and the identifier of the framework;parent slot,the slot value is equal to the framework of its parent event name(the name of slot values common framework,said identifier);subslot,the slot value is equal to each sub-event frame name of the framework(the name of slot values common framework,said identifier),separated by commas;type of slot,logical relations between this event and sub-event,if this event is the bottom event,then its value is the leaf node,otherwise expresses with the logical gate(And gate,Or gate);the rule slot can infer the production rule of the event.The knowledge representation of expert system based on fault tree framework and sets of production rules is shown in Fig.2.

Fig.2 The representation of knowledge framework

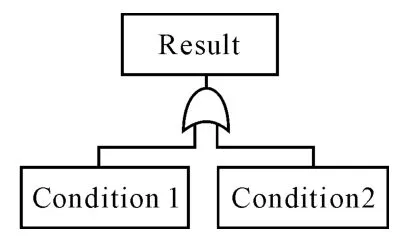

In addition,in order to convert the knowledge of the expand fault tree into production rules,firstly,convert it into a set of“minimum”fault tree,that is each contain only have one fault tree logic gates(and gate,or gate),then convert each minimal fault tree into one or more production rules in diagnosis knowledge.One“and gate”is equivalent to a rule,shown in Fig.3,one“or gate”convert into the rules from which is same as the number of input events of“or gate”,shown in Fig.4.

Fig.3 Relation“And”

Fig.4 Relation“Or”

5.Systen running demo

The common faults of electronic control engine includes:the engine cannot start,the engine start difficult,the idle speed of engine is too high,the idle speed of engine is unsteady and easy to flameout,engine acceleration bad,the engine mixture air is excessive thin,the engine mixture air is excessive thick,the engine loses speed.

6.Conclusions

The study develop a B/Sbased expert system of electronic control engine fault diagnosis which is combine the traditional expert system with fault tree and use the software development tools.The system can realize rapid,accurate and intelligent diagnosis for common faults of electronic engine,and the faults can be diagnosed without disassembly.The system can point out the causes of fault and the exclusion methods,which can avoid blindness of maintenance work and improve maintenance quality.

[1] JI Changwei.Develop of Vehicle Fault Diagnosis System Based on Fault Tree[J].Vehicle and Power Technology,2003(1):52-57.

[2] QI Minghua.Electrical and Electronic Technology of Automobile[M].Beijing:Beijing Institude of Technology Press,2003.

[3] JIANG Hongfeng,JIA Minping.The 4 Reserch on Expert System of Automotive Engine Fault Diagnosis[J].Road& Automotive,2005,110(8):15-18.

[4] ZHENG Wenzhong,CHEN Kaikao.The Reserch on Expert System of Electronic Injection Engine Fault Diagnosis[J].Zhejiang University Journal,2002,28(2):45-48.

[5] DU Lijuan,ZHANG Shifang,YAN Enlei.The Reserch on Expert System of Electronic Injection Engine Fault Diagnosis Based on Fuzzy Neural Nework[J].Hebei Agricultural College Journal,2010,33(9):106-109.

[6] ZHANG Xilin.Electronic Control Technology of Automotive Engine[M].Beijing:Mechanical industry press,2008.