Manufacturing and quality assurance experiences of high temperature components

2013-03-22BaldevRajBhaduri

Baldev Raj,A.K.Bhaduri

(1.President IIW,President INAE,President-Research,PSG Institutions,Peelamedu,Coimbatore 641004,India;2.Indira Gandhi Centre for Atomic Research,Kalpakkam 603102,India)

The term“fast breeder”refers to the types of configurations which can actually produce more fissionable fuel than they use,such as the PFBR.This scenario is possible because the non-fissionable uranium-238 is 140 times more abundant than the fissionable U-235 and can be efficiently converted into Pu-239 by the neutrons from a fission chain reaction.

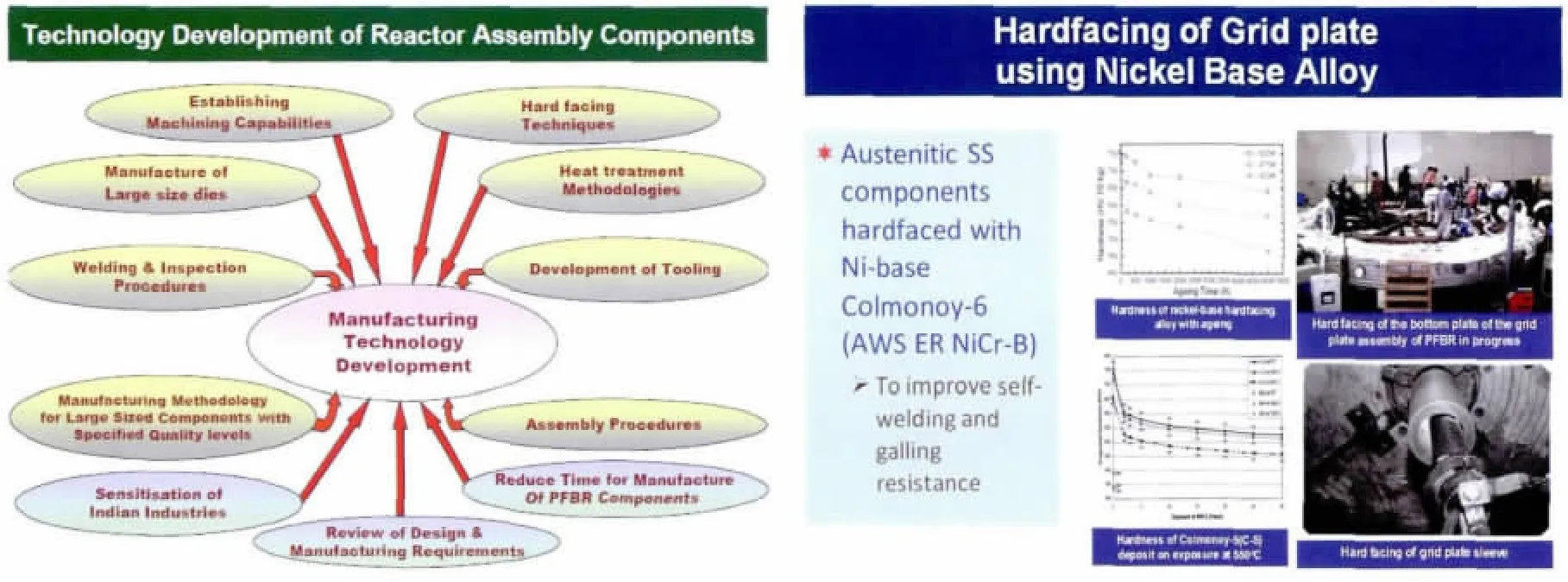

Materials for FBRS includes 316LN,304LN,Carbon steel,9Cr-1Mo steel and Ni-base alloys etc.Fundamentals of design of high performance nuclear reactor components include design and construction codes and standards,proper choice of materials,analyses thoroughly validated tools and factors of safety.

Welding consumables used in different components and piping of PFBR:Thick section welding of shell by narrow-gap TIG (NG-TIG)welding and hot-wire NG-TIG welding process employed first time in India for fabrication of PFBR steam generators.Two important aspects include control of weld defects and proper post weld heat treatment.During fabrication,lamellar tearing was observed during welding of one heat of thick section carbon steel plates.Lamellar tearing was overcome by buttering plate surface by welding (as permitted in ASME)and by changing joint design.Tube-to-Tube sheet welding in Intermediate Heat Exchangers is difficult and important.Each IHX has 3600 straight seamless tubes and 150 mm thick forging welded to either ends of top and bottom tube sheets.

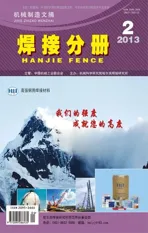

IGCAR (Department of Atomic Energy,Government of India)realizes importance of welding and subsequent inspection of welds both during fabrication and in service.This has enabled overcoming challenges faced during fabrication of components and piping with stringent specifications.IGCAR has mastered technology for in-service-inspection of reactor components under highly demanding environment of high temperature liquid sodium and high radiation level.Experience gained in PFBR construction is vital in design and construction of Commercial Fast Breeder Reactors (CFBRs).

Typical graphic