沸石填料BAF和组合填料BAF启动挂膜对比试验

2012-03-12孙兴滨潘华崟孙永锋崔福义赵志伟

孙兴滨,潘华崟,孙永锋,崔福义,赵志伟

(1.东北林业大学环境科学系,哈尔滨150040;2.哈尔滨工业大学市政环境工程学院,哈尔滨150090)

Biological Aerated Filter integrated various purification functions such as filtration,adsorption and biological metabolism,which has many advantages for instance small floor area,better effluent quality,simple flow,little influence on environment[1].In the U-nited States and Japan,there are more than 50 BAF treatment facilities put into operation early in 1990s.the application of Biological Aerated Filter in feed water treatment is being a research hot spot[2-3].

The filler is the core part in Biological Aerated Filter,and its surface structure,physical and chemical properties are very important to attached growth Micro Biologics[4-6].At present,research members from domestic and abroad study on the single packing Biological Aerated Filter more than combined packing.In this paper,we will analysis on start-up of biological Aerated Filter with zeolite and zerlite-Biochemical cotton filler,and explore the pollutant removal characteristic of two fillers during start-up.

1 Materials and methods

1.1 Experimental device and materials

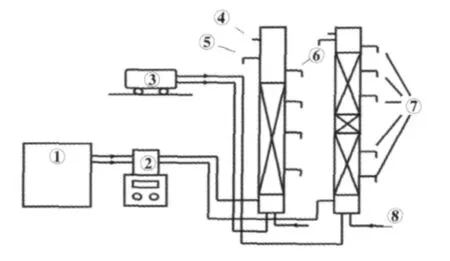

The BAF reactor is processed into columnar structure with plexiglass that its wall thickness is 5 mm,the inner diameter is 30mm and the height is 1 500 mm.Two fillers are used by parallel operation.1#columnar contains 2~3 mm zeolite filler,the thickness is 600 mm,and there is a sampling port located every 200 mm.The thickness of filter supporting bed is 100 mm.2#columnar contains combined packing,the middle of upper layer and lower layer is separated by the porous plate.The height of 2~3 mm zeolite filler in the upper layer is 300 mm,and there is a 100 mm gravel filter supporting bed at the bottom.The suspended filler is in the lower layer.The experimental device is shown in Figure 1.

Figure 1 Experimental device①Water tank;②Peristaltic pump;③Air pump;④Overflow port;⑤Backwashing effluent;⑥Effluent port;⑦Sampling port;⑧Backwashing influent

1.2 Measurement items and measurement items and methods

1.3 Start-up process

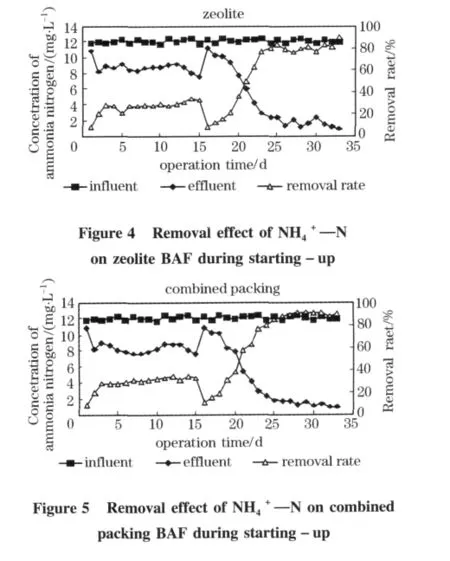

The experiment adopted the method of compound start-up with inoculums of polluted surface water. the direction of influent was upflow.First filled the experimental equipment with activated sludge,then only aerated.Changed small flow influent after only aerated continuously for six days(changing the water every three days),And gradually increase the water flow to the design flow.In the conditions of the temperature was 16~24℃,HRT was 1h and DO was 6 mg/L,let microorganisms gradually adapt influent quality.During starting-up,permanganate index and ammonia nitrogen were measured everyday.Water quality of test sample was shown in Table 1.

Table 1 Water quality of test sample

2 Result and discussion

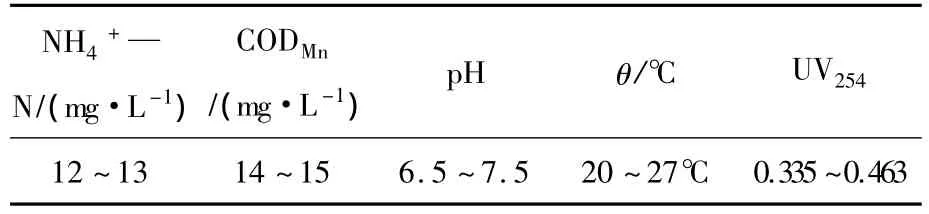

2.1 Removal effect of CODMn

As can be seen from Figure 2 and 3,CODMnof influent was in the 14~15 mg/L,after 5 days since BAF process had been starting-up,CODMnof effluent in 1#and 2#was 11.57 mg/L and 11.48 mg/L respectively.It showed that biofilm on the zeolite was not mature at this stage,the removal effect mainly depended on zeolite adsorption.But this adsorption was limited.Previous study showed that zeolite only removed larger molecular organics of natural water,it had bad removal effect on small molecular organics.The removal rate in 2#was higher than 1#,the reason that besides zeolite adsorption in the upper layer,suspended carrier in the lower layer also played a role in interception.In the fifteenth day,removal rate of CODMnrespectively reached 22%and 26%,it showed that heterotrophic bacteria had been a mass growth and played a role in the degradation of organic compounds.In 33th day,the removal rate was 27%and 32%respectively,indicated that quantity of heterotrophic bacteria was the maximum and stable.Biofilm had been maturity,except that the degradation of permanganate,microorganism flcos of the biofilm also reduced the gap between fills,played adsorption and filtration on organic in the water.

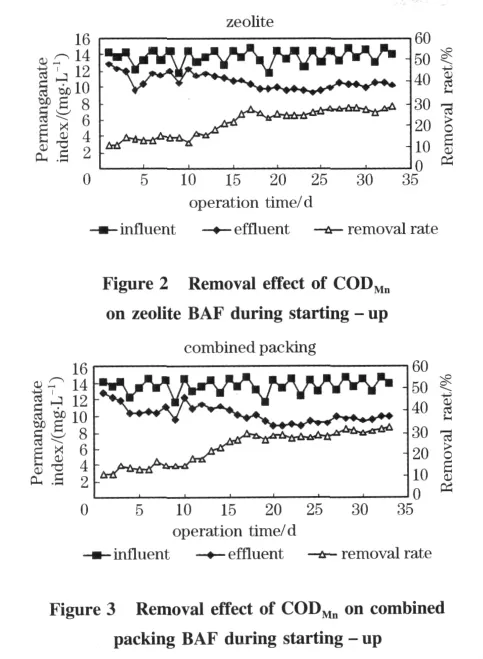

2.2 Removal effect of

3 Conclusion

1)Using the BAF process study on Start-up of Biological Aerated Filter with zeolite and zeolite-biochemical cotton filler.Under the same condition,biofilm culturing had been successfully after 33 days.

2)The removal rate of CODMnand NH4+—N on zeolite BAF is 27%and 84%respectively;the removal of zeolite-biochemical cotton filler BAF is better.The removal rate is 32%and 92%respectively.

[1] CANLER J P.Biological Aerated Filters:Assessment of the process based on 12 sewage treatment plants[J].Wat Sci Tech,1994,29(10-11):13-22.

[2] STEPHENSON T,MAN A,UPTON J.The small footprint wastewater treatment process[J].Chemistry&Industry,1993 (19):533.

[3] GILBERT D,FRANK R.Biofiltration as a compact technique for small wastewater treatment plant[J].Sci Tech,1990,22 (3):145.

[4] FATIHAH S,DONNELLY T.Effect of media volume on mixing of biological aerated filters[J].J.Environ.Eng.Sci.,2008,7: 229-236.

[5] MOORE R,QUARMBY J,STEPHENSON T.The effects of media size on the performance of biological aerated filters[J].Water Science and Technology,2001,35(10):2514-2522.

[6] MANN A T,MENDOZAESPINOSA L,STEPHENSON T.Performance of floating and sunken media biological aerated filters under unsteady state condition[J].Water Research,1999,33 (4):1108-1113.