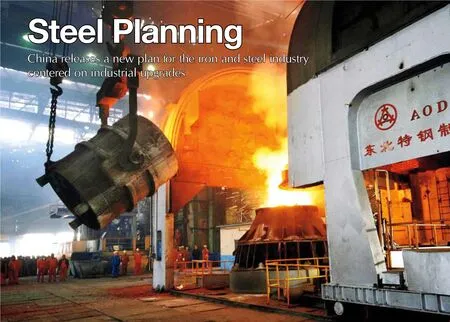

Steel Planning

2011-10-14ByWANGJUN

By WANG JUN

Steel Planning

By WANG JUN

China releases a new plan for the iron and steel industry centered on industrial upgrades

The new 12th Five-Year Plan (2011-15) for China’s iron and steel industry, recently released on the website of the Ministry of Industry and Information Technology (MIIT), says the iron and steel industry will face development opportunities, as well as severe challenges, particularly slowed growth in market demand and growing pressure to protect the environment.

MIIT figures show that during the 11th Five-Year Plan period (2006-10), China’s crude steel output increased from 350 million tons to 630 million tons, an annual average growth of 12.2 percent. The market share of domestic companies rose from 92 percent to 97 percent. In 2010 the output value of the iron and steel industry reached 7 trillion yuan ($1.11 trillion), accounting for 10 percent of the country’s total industrial output. The total assets of the industry stood at 6.2 trillion yuan ($979.46 billion).

“The plan was issued after repeated deliberations. It will greatly improve confidence in the iron and steel industry as well as some other related industries and will play an effective role in encouraging overseas investment in steel companies and solving the predicament of iron ore,” said Ma Zhongpu, Deputy General Manager and chief analyst of Chinaccm.com (China Commodity Marketplace).

A research report released by China International Capital Corp. Ltd. on November 8 says the plan shows the government’s resolution and direction to restructuring the iron and steel industry. In the short term, the plan will stimulate market sentiment, and in the long term, if the plan can be implemented effectively, it will improve the industrial structure, enhance competitiveness of the iron and steel industry in the whole industrial chain.

Achievements and challenges

Luo Tiejun, former director of the Raw Material Industries Department of the MIIT, summed up the achievements of China’s iron and steel industry during the 11th Five-Year Plan period, “During the fve years, the iron and steel industry experienced rapid growth with the most remarkable improvements in energy conservation and emission reduction. The fve years also saw an increasingly important role played by the market in resource allocation and the development of various steel companies, all effectively supporting the steady and rapid development of the national economy.”

According to Luo, the plan gives four basic judgments on the iron and steel industry. First, the scale of the iron and steel industry is large enough to serve the transformation of the industry. Second, the industry still faces increasing restrictions of resources, energy and raw material price hikes. Third, the development environment is becoming more complicated, and mutual impact between China’s iron and steel industry and the world economy grows. Fourth, the industry has entered a key stage in transforming its development pattern.

“The iron and steel industry will stay with low profts for a long time and it is time that the industry transforms its development pattern,” Luo said.

1. MORE EFFICIENT PRODUCTION: A refinery upgraded with a high energy-consuming furnace at Dalian Jinniu No.1 Steel Smelting Factory of Dongbei Special Steel Group Co. Ltd.

3. GUARANTEEING SUPPLIES: Fine ores are piled up at the freight yard of Fangchenggang Port, Guangxi Zhuang Autonomous Region

L

2. KEEPING A CLOSE EYE: A worker monitors machineryat the Dalian workshop of Dongbei Special Steel Group Co. Ltd.

Luo also analyzed four major problems.

First, the varieties and quality of steel products urgently need to be upgraded.

“At present product varieties and quality can meet demand featuring high consumption with low standards, or a crude demand,” Luo said.

Second, readjustment of the industrial layout is proceeding slowly. According to Luo, southeast China still lacks production capacity. At present, the fve provinces and municipalities around the Bohai Sea produce 400 million tons of steel products annually, with half consumed by themselves and the other half transported to the southeastern region. During the 12th Five-Year Plan period, efforts will be made to boost the steel production capacity in southeast China.

Third, the industry faces heavier restrictions on energy and raw materials in addition to mandates to protect the environment. Luo thought environmental issues are particularly challenging, and the iron and steel industry must solve the problem of reducing emissions of carbon dioxide. Since the iron and steel industry is a major energy consumer, it must frst start by saving energy to reduce carbon emission. Luo said the industry should also regulate the iron ore market and explore measures to maintain the sound development of both upstream and downstream industries.

Fourth, the industry’s capacity for independent innovation is still weak. “During the 12th Five-Year Plan period, what will the iron and steel industry depend on to transform its development pattern? The key point is technology innovation,” Luo said.

The Chinese steel industry still has many deficiencies. Lacking experienced professionals with technical know-how, many steel companies fnd their development held back by limited technological innovation capacities. Further most, research and development facilities operate on barebones budgets, causing an absence of core technologies.

Targets set

The plan sets six targets for the iron and steel industry in the next fve years, including upgrading its line of products and improving product quality. It requires broadening scale production of such products as silicon steel sheets and increasing the market share of domestic producers to 90 percent. Meanwhile, 80 percent of high-end products such as marine corrosion-resisting steel needed in the Chinese market should be produced by domestic companies.

As for energy saving and emission reduction, the plan sets stricter targets than the one for the whole country. According to Luo, China’s 12th Five-Year Plan sets a goal to reduce energy consumption per 10,000 yuan ($1,579.78) of GDP by 16 percent, while the plan for the iron and steel industry sets a stricter goal of 18 percent. In the meantime, the plan requires that the energy consumption for each ton of steel products should be lower than 580 kg of standard coal.

The plan proposes to improve the layout of the iron and steel industry. Zhao Liming, researcher at Hongyuan Securities Co. Ltd., said most of China’s steel production capacity has been in the north, while south China has been facing serious shortages in supply due to fast economic growth. Hence the plan proposes that during the 12th Five-Year Plan period, the country will build two new iron and steel bases in Zhanjiang, Guangdong Province, and Fangchenggang, Guangxi Zhuang Autonomous Region, and promote the construction of an iron and steel production base in Ningde, Fujian Province, to thoroughly reverse the short supply of steel products in southeast China’s coastal areas.

The plan prioritizes enhancing China’s capability of guaranteeing resource supplies for the iron and steel industry. A guarantee mechanism for iron ore and coal fuels will be established, and 100 million tons of overseas production capacity of iron ore will be added. The plan also requires regulating the domestic iron ore market and enhancing exploration of domestic iron ore resources.

The plan also proposes to establish a sound mechanism for technology innovation. Steel companies should invest no less than 1.5 percent of their sales revenues in research and development. Progress should be made in independent innovative techniques such as low-carbon smelting and comprehensive resource utilization, and technologies for highly efficient production as well as energy saving and emission reduction should be widely used.

Industrial concentration will be increased, said the plan. By 2015, the top 10 steel companies will produce 60 percent of the country’s total steel output, compared with the proportion of 48.6 percent at the end of 2010 and 34.7 percent at the end of 2005.